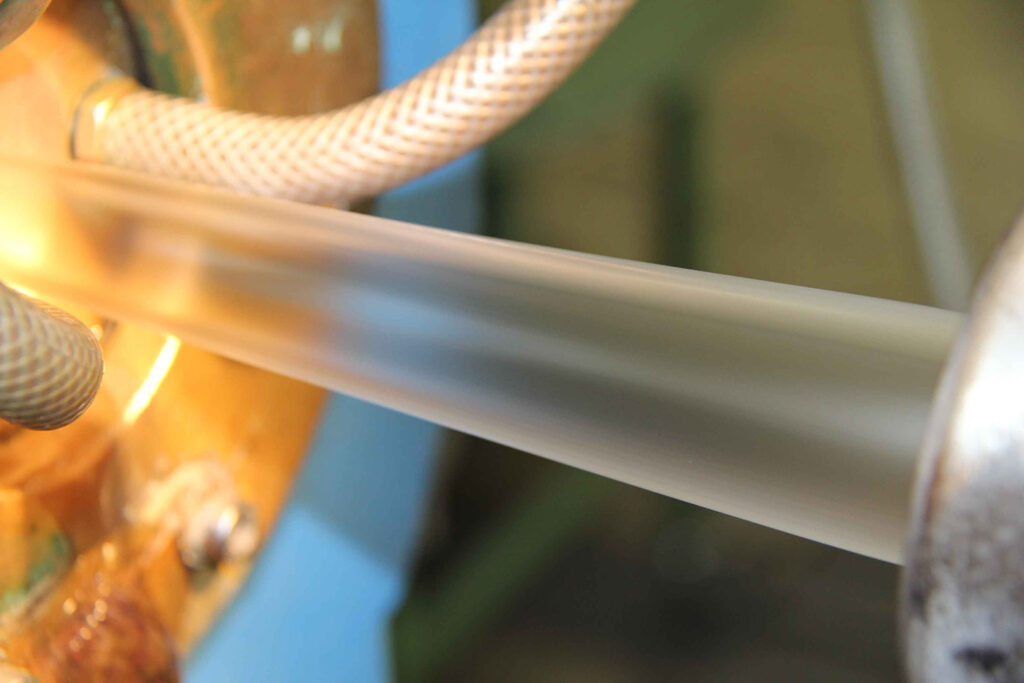

The production of high-quality pipes requires continuous quality monitoring from the delivery of the material to the finished product. Our quality assurance is based on the testing and monitoring regulations of the Süddeutsches Kunststoffzentrum (SKZ) and, in the future, other European testing institutes.

Every delivery of pipe is tested for the melt flow index in accordance with DIN 53735, as this is decisive for the subsequent quality of the pipe. Only flawless goods are released for production.

During pipe production, the production process is continuously monitored 100%. The dimensional accuracies of wall thickness and outside diameter as well as the surface finish are controlled and documented accordingly. We use only raw materials that meet the requirements of EN ISO 22391. Our pipe construction – UNATHERM Systems PRO5 – meets the high requirements of the composite pipe standard DIN EN ISO 21003. The oxygen tightness of our products complies with DIN 4726, which we test both at the regular 40°C and at 80°C according to KOMO’s higher requirement profile.

Finally, after completion, the change in the pipes after heat storage, the homogeneity of the material and the pressure stability under the influence of temperature are tested in our in-house laboratory.